The production area has an area of 1383 m2 and is fully equipped with high-tech machinery for value-added production. This area has the potential to process polymer plastics using metalworking, woodworking, additive manufacturing, and machining.

In the production zone there are more than 50 types of equipment that meet the latest world standards.

This area also includes a fully equipped VR zone for your virtual reality projects.

Here you can start your own production or order a product for your innovative projects.

One of the main advantages of laser cutting is high precision and repeatability

it is an industrial tool used to bend metal sheets at precise angles.

These machines are able to provide high precision and clean cuts

It is designed for drilling, reaming, as well as internal threading, centering, etc. operations.

They are designed to form a variety of materials, including steel, aluminum, and other materials.

complete maintenance of surface deformation of parts, availability of small thickness, working with surfaces of any hardness

Spot welds metal sheets up to 3 mm thick

plastic products are made by melting molten polymer raw materials into a metal mold

works on cylindrical logs with a length of 1000 mm.

Metal 3d printing machine.

Wooden rover bench

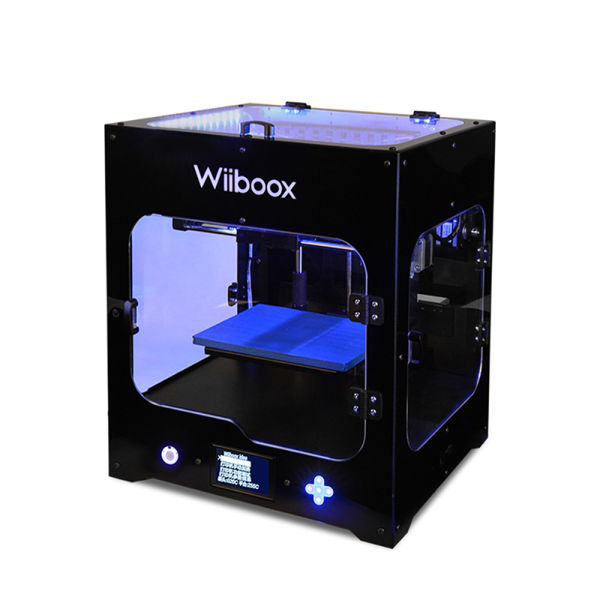

3D printer with high accuracy and speed